Circular Reliability Meets

With more than 70 years of engineering excellence in essential water infrastructure, CROM is proud to continue its legacy as an innovator in the field with the introduction of CROM2—our state-of-the-art watertight tensioned straightwall tank, engineered to surpass industry standards and redefine durability.

Unrivaled longevity

CROM2 is a composite straightwall storage tank designed to stay watertight throughout its lifespan. This tank features a galvanized steel shell encased in shotcrete, with specially designed joints and corner posts that support watertight connections. The structure is kept in persistent compression by post-tensioning, which helps maintain its integrity without the need for additional coatings or frequent repairs.

Notable durability

CROM2 tanks can be tailored for various sizes, offering a low-maintenance, durable solution for storing water or wastewater. They are especially beneficial for tanks between 15,000 and 1.5 million gallons, providing a practical and efficient option for many facilities.

Dependable value

CROM2 tanks are meticulously designed and constructed from decades of experience, quality, and innovation, setting a standard for excellence in the water industry. Backed by our CROM Standard Five-Year Warranty, you can expect unsurpassed safety and reliability, at the lowest life cycle cost, with CROM2 watertight tensioned straightwall tanks.

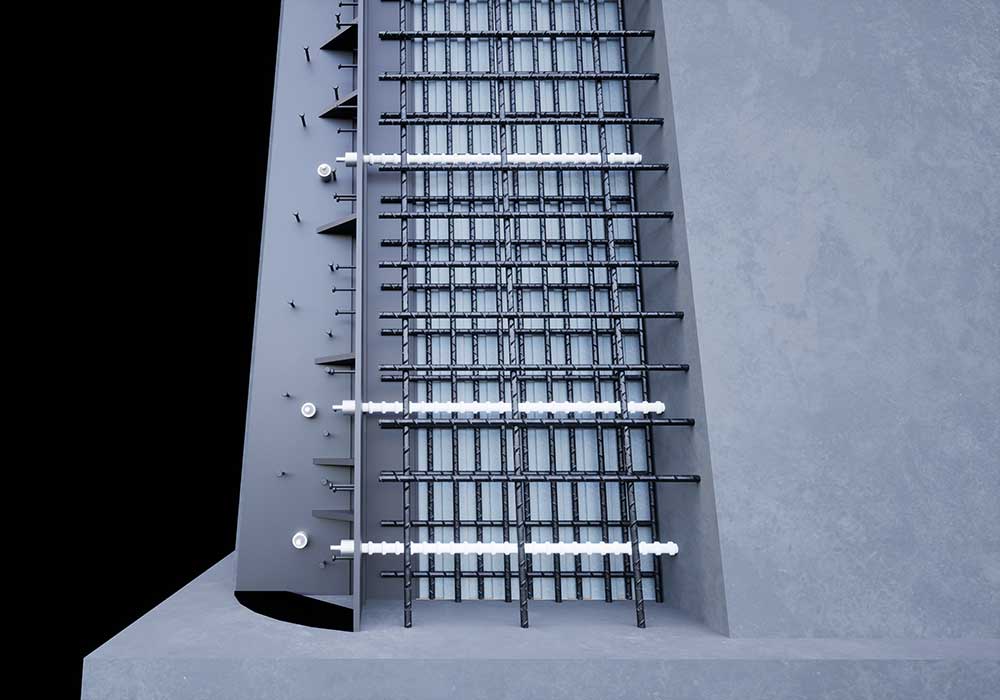

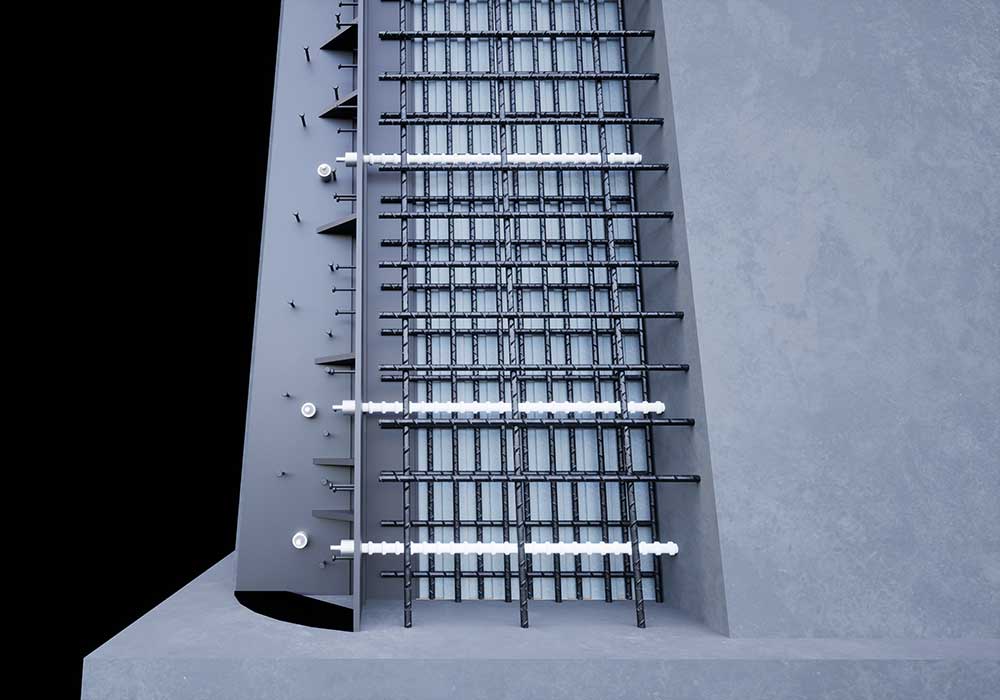

CROM2 Core Wall Features

Required to withstand hydrostatic load along the composite straightwall

1 of 8 Steel Shell DiaphragmContinuous without horizontal joints and fully encased in continuous shotcrete

2 of 8 Vertical JointsSealed with epoxy injection after the steel shell has been encased with shotcrete

3 of 8 Shotcrete Core WallThickness required to withstand hydrostatic along the composite straightwall

4 of 8 Coating SystemOptional

5 of 8 Plastic DuctProvides annular space to bond post-tensioning strand

6 of 8 Shotcrete CovercoatProtects vertical and horizontal reinforcement

7 of 8 Post-Tensioning StrandKeeps composite straightwall in compression

8 of 8CROM2 engineered connection details

Floor-to-wall

The floor and wall of the tank are connected using a specially designed groove near the base. This groove allows a vertical steel layer to be securely sealed into place with materials like epoxy or grout, ensuring a strong, watertight bond. Once sealed, the entire structure is reinforced with a protective concrete layer to keep it durable and leak proof.

Floor-to-wall

The floor and wall of the tank are connected using a specially designed groove near the base. This groove allows a vertical steel layer to be securely sealed into place with materials like epoxy or grout, ensuring a strong, watertight bond. Once sealed, the entire structure is reinforced with a protective concrete layer to keep it durable and leak proof.

External wall

Straight walls are securely joined at 90-degree angles with a special sealant that ensures they stay tightly connected. The walls are reinforced with tension, pressing them together to create a strong, leak-proof structure. The entire tank is then coated with a smooth, protective concrete layer, making it durable and watertight without the need for additional coatings or crack fillers.

External wall

Straightwalls are securely joined at 90-degree angles with a special sealant that ensures they stay tightly connected. The walls are reinforced with tension, pressing them together to create a strong, leak-proof structure. The entire tank is then coated with a smooth, protective concrete layer, making it durable and watertight without the need for additional coatings or crack fillers.

Bisecting wall

A bisecting wall junction plate allows internal walls to connect seamlessly within the tank, ensuring the entire structure stays watertight and strong. This connection uses a steel plate that fits securely into a groove, linking the walls together and preventing leaks. The design can include multiple connections for walls that meet at different angles, keeping the entire tank secure and leak proof.

Bisecting wall

A bisecting wall junction plate allows internal walls to connect seamlessly within the tank, ensuring the entire structure stays watertight and strong. This connection uses a steel plate that fits securely into a groove, linking the walls together and preventing leaks. The design can include multiple connections for walls that meet at different angles, keeping the entire tank secure and leak proof.

Corner

Each of the four tapered walls of the tank is joined at the corners using a specially designed post that connects the walls at a 90-degree angle. This corner post is shaped to handle the necessary pressure and ensure a watertight seal. It includes unique slots and tensioning features that keep the structure tightly compressed and leak-proof. The post can be made into various shapes, such as L, T, or square, to fit the design, and it works to keep the tank secure by applying pressure in two directions.

Corner

Each of the four tapered walls of the tank is joined at the corners using a specially designed post that connects the walls at a 90-degree angle. This corner post is shaped to handle the necessary pressure and ensure a watertight seal. It includes unique slots and tensioning features that keep the structure tightly compressed and leak-proof. The post can be made into various shapes, such as L, T, or square, to fit the design, and it works to keep the tank secure by applying pressure in two directions.